Industrial Electrician, Electrical Contractors Near Me in Denver, Commerce City, Brighton, Greeley, Loveland, Windsor, Fort Collins, CO.

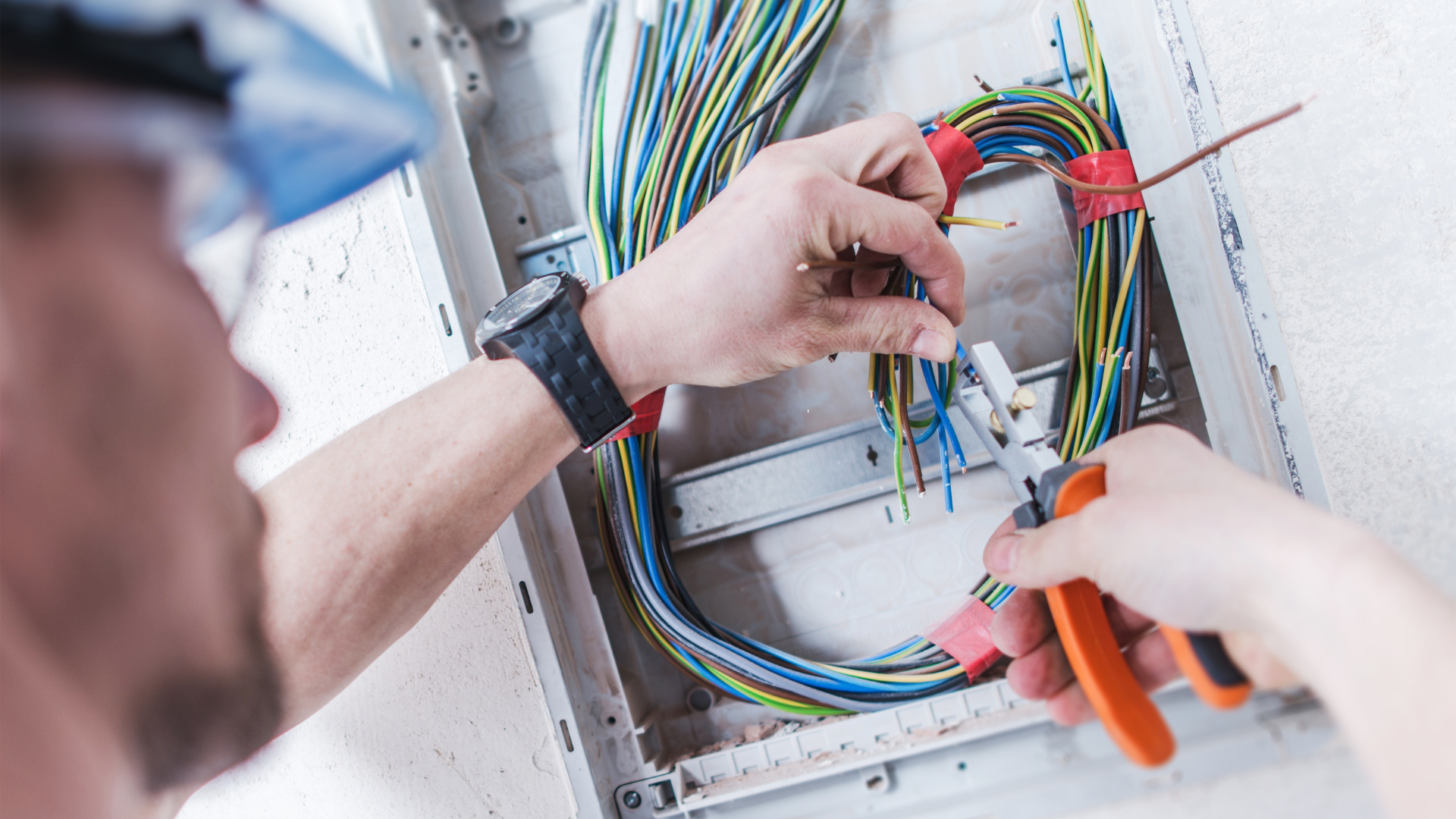

Industrial Electricians

Near You, Wiring, Repairs, Certifications, Affordable

industrial Electrical, Industrial Electrical Services, Commercial and Industrial Electrical Contractors

Satisfaction Guaranteed

Industrial Electrical Contractors, Contractors, Installation, Repairs

Get a free quote today

Contact Us

Recent Industrial Electrical Projects

Every Industrial electric project comes with its own needs and challenges. Tell us your Industrial Electric priorities, and we'll have your Industrial electrical machines fixed quickly.

Industrial Electricians Near Me

Industrial Electrical Contractor, Industrial Electric Heaters, Generators, Industrial Electricity, Wiring, Installation, Repair.

Industrial Electricians Near Me, Denver, Commerce City, Brighton, Greeley, Loveland, Windsor & Fort Collins, CO.

Industrial Electrician Near me

ACDC Electric, a reliable Industrial Electrician Near Me, is crucial for businesses in cities like Denver, Commerce City, Greeley, Loveland, Windsor, and Fort Collins.

An Industrial Electrician Near You can address electrical issues promptly, ensuring minimal downtime and enhanced safety for industrial operations, whether routine maintenance or emergency repairs.

As experienced Industrial Electricians Near You, We can be onsite quickly and we offer the expertise needed to keep systems running efficiently. Businesses in Denver and surrounding areas can benefit from the specialized skills of an Industrial Electrician Near me, ensuring compliance with industry standards and reducing operational risks.

Industrial Electrical Contractors

Industrial Electrical Contractors are crucial in cities such as Denver, Commerce City, Greeley, Loveland, Windsor, and Fort Collins. These cities rely heavily on Industrial Electric Contractors maintain the efficiency and safety of their Industrial manufacturing and production facilities. Whether installing new electrical systems or upgrading existing ones, Industrial electric companies ensure that industrial businesses operate without disruptions. In Denver and surrounding cities, the demand for specialized Industrial Electric continues to grow, driven by the expansion of commercial and industrial sectors. Partnering with experienced Industrial Electric providers guarantees compliance with regulations and enhances operational productivity across these key Colorado locations.

Frequently Asked Question's- Industrial Electricians

What Solutions Are Available for Power Upgrades and Backup Solutions?

Power Upgrade and Backup System Solutions

When it comes to enhancing your facility’s electrical capabilities, a range of solutions can be tailored to meet your specific needs, whether you're looking for a complete overhaul or a focused upgrade.

Comprehensive Power Enhancements

Full or Partial Power Upgrades: Whether you need an entire system revitalization or targeted improvements, customized solutions are available. These upgrades ensure your power system is robust and efficient.

Backup Solutions for Peace of Mind

Emergency Power Services: In critical situations, 24/7 emergency power services are essential, keeping your operations running smoothly without interruption.

Standby Generators: Equip your facility with reliable standby generators to prepare for unforeseen power outages. These systems automatically kick in to provide consistent power.

Uninterruptible Power Supply (UPS) Systems: Maintain continuous power to vital equipment with UPS systems. They're ideal for protecting sensitive electronics and ensuring data integrity during power disruptions.

Backup Lighting: Ensure safety and visibility with backup lighting solutions that activate during power failures, keeping your environment safe and functional.

Investing in these power upgrade and backup solutions ensures your operations remain resilient and dependable in any situation.

How Does the Contractor Handle Control Wiring and Motor Controls?

Handling Control Wiring and Motor Controls

When it comes to enhancing and upgrading control wiring, the contractor adopts a comprehensive approach. They don't just make tweaks; they undertake full rewiring of machines to ensure optimal functionality and safety. This meticulous process involves evaluating existing systems, identifying problem areas, and implementing state-of-the-art solutions.

For motor controls and transformers, the contractor provides both design and installation services. They tailor each project to meet specific needs, ensuring efficient energy use and seamless integration with current systems. From initial design concepts to the final installation, every step is planned and executed with precision.

Whether upgrading an outdated system or installing a new one, this contractor prioritizes reliability and performance, delivering solutions that enhance operational effectiveness.

What Methods are Used for Power Quality Monitoring and Maintenance?

Methods for Power Quality Monitoring and Maintenance

When it comes to ensuring optimal performance and longevity of electrical systems, implementing effective power quality monitoring and maintenance techniques is crucial. Here are some of the most widely-used approaches:

1. Power Quality Monitoring and Analysis

Real-Time Monitoring: Advanced meters and sensors provide continuous data on electricity usage, helping identify disturbances such as voltage sags, spikes, and harmonic distortions. This real-time data is crucial for maintaining system stability and efficiency.

Data Logging: By recording power parameters over time, data loggers allow for historical analysis, helping to trace the root cause of recurring issues or unexpected power quality events.

2. Predictive Maintenance with Infrared Technology

Infrared Thermography: This non-invasive technique uses thermal imaging cameras to detect abnormal heat patterns in electrical components, which may indicate issues like loose connections or overloading. By identifying these hot spots early, it prevents serious failures and reduces downtime.

3. Regular Equipment Inspections

Visual and Physical Checks: Regularly inspecting electrical panels, connections, and equipment for signs of wear and damage can prevent potential failures.

Testing Insulation and Grounding: Routine tests ensure that insulation and grounding are in optimal condition, preventing faults and ensuring safety.

4. Harmonic Analysis and Correction

Harmonic Filters: Installing these devices helps mitigate the effects of harmonic distortions, ensuring that power systems operate smoothly and efficiently.

5. Load Imbalance Correction

Phase Balancing: Adjusting loads across different phases keeps electrical systems running efficiently, minimizing energy losses and preventing equipment stress.

By employing these strategies, businesses can enhance their electrical systems' reliability, reduce operational costs, and maximize the lifespan of their equipment.

What is an Example of a Turn Key Project Completed by the Contractor?

One notable example of a turn-key project completed by the contractor is the successful execution of a comprehensive coil slitting line installation. The team handled everything from the initial construction to the final commissioning of this new machinery. Their expertise ensured that the entire process, which included both electrical and structural components, was seamlessly executed. This allowed the facility to swiftly begin operations, demonstrating the contractor's ability to deliver fully operational solutions tailored to client needs.

How Can a Business Distinguish Between Quality Industrial Electrical Contractors and Others?

Identifying top-tier industrial electrical contractors amidst a sea of choices can be challenging. However, businesses can pinpoint quality professionals by focusing on key differentiators. Here's how:

Experience and Expertise: Leading contractors often boast a proven track record, showcasing extensive experience across diverse industrial projects. Their portfolio should reflect their ability to handle complex electrical systems in various industries.

Certifications and Credentials: Verify that the contractor holds relevant licenses and certifications, such as those from the National Electrical Contractors Association (NECA) or certification programs like OSHA.

Customer Reviews and Testimonials: Peruse customer feedback on platforms like Yelp or Better Business Bureau to gauge client satisfaction and the contractor’s reputation.

Technology and Innovation: The best contractors stay ahead by integrating cutting-edge technology and modern techniques, ensuring they meet current industry standards while also planning for future needs.

Safety Standards: High-quality contractors prioritize safety, adhering strictly to safety regulations and maintaining comprehensive safety programs to protect their workers and your facility.

By assessing these factors, businesses can confidently select industrial electrical contractors who excel in quality and reliability.

Quick & Reliable Industrial Electrician Near Me

We are always available to service your Industrial Electric needs.

Latest Blog Posts